We live in an automated world. Our drive around town is regulated by automated traffic signals that switch color lights on and off to govern the flow of traffic. Our homes are heated by automated systems that know when to turn on and off.

Home security systems detect movement and can even provide live video to our mobile device. Home appliances, like washing machines, automate important processes to help us live our lives.

These devices are becoming more and more sophisticated through the use of the programmable logic controller, or PLC.

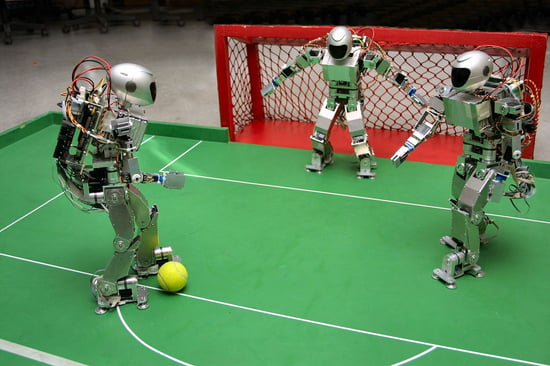

If our homes are becoming highly automated, think about what is going on in the manufacturing sector. Today's high-tech factories are light years more advanced than the assembly lines of yesteryear. Banks of robots weld car doors and assemble vehicles. Computers control ovens and conveyors to create our food.

The days of people slaving over an assembly line are gone. Modern factories in the technology, medical and food sectors use advanced robotics and automation to produce the goods that we use everyday.

Behind all this automation is the programmable logic controller. This tiny device drives the economic engines of our world to more efficient production.

This is good news if you are looking for a good career. PLCs have so many applications that PLC technicians will always be in demand. Training with the programmable logic controller can lead to a cutting-edge career in automation.

Taking a PLC class or getting a PLC certification are good steps into this exciting field.

What Is a Programmable Logic Controller?

Let's start simple: think about your thermostat. You turn the dial to your desired temperature, and your heating system kicks in to make your home that temperature. The thermostat senses the current temperature of the room and can compute the difference between the desired temperature and the current temperature.

If the temperature is too warm, the heating system will not turn on and the room will slowly loose energy. Once the room temperature becomes lower than the desired temperature, the heater turns on to warm up the room.

In time, the room temperature should always be relatively close to the desired temperature. With just the turn of a dial, your heating system automatically adjusts to your desired temperature.

The thermostat is a very basic programmable logic controller. It is a device that responds to external events and conditions to produce a desired outcome.

There are more complicated thermostats that can regulate different zones of your home and even integrate cooling into the system as well. These thermostats require computers to process the information about conditions in your home and respond by controlling your HVAC system accordingly.

A programmable logic controller is a small computer that monitors input from sensors and, based on this information, controls output devices. The PLC contains programming that can make decisions based on the sensor input about external events and environmental conditions.

These decisions translate into output that controls machinery, pumps, fans and even complicated robots to produce a desired result.

The PLC is the nerve center of any automated process. It processes input from the environment and responds by controlling devices.

PLCs are everywhere, but you probably don't notice them. Elevators require PLCs to control their travel between floors of a building. Car washes use them to automate the washing process. Industrial assembly lines use PLCs to control the various machines and conveyors used in the manufacturing process. The applications are endless.

Anywhere there is an automated process that responds to environmental conditions and events, there will be PLCs making decisions about how to produce the desired outcome. And these PLCs will need programmers and technicians to make them work.

Automation and Robotics Jobs

The incredible technological advances in industrial automation and robotics present an incredible opportunity for those who can program, install and maintain PLCs.

-

PLC programmers work with mechanical and electrical engineers to design the automation for today's high-tech industrial factories.

-

Once the overall manufacturing system is designed, the PLC programmers must write the computer code that allows the PLCs to control the overall process.

-

PLC technicians work on the factory floor to install and maintain the PLCs. They make sure the industrial system is up and running with minimal down time.

Many PLC jobs are in the automotive industry, but food processing plants and medical device manufactures also employ many of these skilled workers. Nearly every modern factory uses PLCs to regulate the manufacturing process.

This means that the job outlook for PLC technicians and programmers is good. There is a strong and growing demand for people with these skills. Compensation is also good with an average annual salary of $61,000. This is certainly a good field to consider if you possess the technical aptitude required.

How to Become a PLC Programmer or Technician

Good news! It is not hard to get the training required to learn about programmable logic controllers. You don't need to get a four-year degree in engineering to acquire the skills necessary to enter this field. Many colleges offer a two-year mechatronics program where you can get an Associate's degree or a PLC certificate.

These programs combine classes in PLC programming with the basics of mechanical and electrical engineering. They are aimed at giving the skill set required to serve in this growing field.

Want to find out if PLC programming is for you? Try out this introductory PLC programming course through Idaho State University's Continuing Education and Workforce Training program. In this self-paced online course, you can explore the basics of PLC programming and get started on the path to a new and exciting career in automation and robotics.

.png?width=220&name=Do%20You%20Pocatello%20Podcast_%20(1).png)